"Superior visibility": Improved visibility in Digital Display

|

Improvements to the digital display deliver a wide viewing angle along with increased clarity. The display pressure range and set pressure range have also been increased.

|

|

"Long-distance transmission of analog output": Addition of analog current output capability to multifunctional models

Users can now select either voltage output or current output as analog output according to their application.

"Reduced environmental impact": 14% lower power consumption (during normal operation)

|

Thanks to a redesign of its circuitry, power consumption of the low-power-consumption DP-100 series during normal operation has been reduced by 14%. The display is shut off entirely during ECO / FULL mode operation for power savings of up to 50% compared to normal operation, and display brightness is lowered during ECO / STD mode operation for power savings of up to 30% compared to normal operation.

|

|

Addition of a reverse polarity protection circuit to the transistor output circuit

To prevent from breakage due to miswiring.

Dual display allows direct setting of threshold value

Equipped with a 30 mm 1.181 in square compact-sized dual display. The current value and the threshold value can be checked at the same time, so the threshold value can be set and checked smoothly without switching to another screen mode. ON / OFF operations still continue while the threshold values are being set, so setting to the same sensitivity as dial control-type sensors is possible. Key lock function is equipped as well.

3-color display (Red, Green, Orange)

The main display changes color in line with changes in the status of output ON / OFF operation, and it also changes color while setting is in progress. The sensor status can therefore be understood easily, and operating errors can be reduced.

Readable digital display

|

12 segments are used and an alphanumeric display has been adopted. This improves visual checking of letters and numbers.

|

|

|

Copy function reduces man-hours and human error

Sensors can be connected to a master sensor one by one, and a copy of the setting details for the master sensor can be transmitted as data to other sensors. If making the same settings for multiple sensors, this prevents setting errors among other sensors and in addition, when machinery design are changed, there would be less change in work orders.

|

Setting details can be copied.

|

|

| Note: |

Settings cannot be copied from the new version (Ver. 2) to the old version.

However, settings can be copied from the old version to the new version (Ver. 2). |

|

|

|

Advantage 1:Setting man-hours are reduced and sensor setting time is shortened.

The setting details for the master sensor are retained, so continuous copying is possible. For 2nd and subsequent lines, the data transmission time only is required.

|

|

|

Advantage 2:Human operating error is reduced.

・Because all details are copied automatically, problems as a result of human error can be prevented.

・Instruction manuals can be updated easily when changes are made to equipment design.

The sensor’s setting operation mode has a 3-level configuration to suit the frequency of use.

|

The setting levels are clearly separated into "RUN mode" for operation settings that are carried out daily, "MENU SETTING mode" for basic settings, and "PRO mode" for special and detailed setting. These make setting operations easy to understand and easy to carry out.

|

|

|

|

RUN mode

Settings such as threshold value adjustment and key lock operation can be carried out while the sensor is operating.

|

|

|

|

MENU SETTING mode

Basic settings such as output mode setting and NO / NC switching can be carried out.

|

|

|

|

PRO mode

High-level function settings such as hysteresis adjustment and the copy function can be carried out.

|

|

|

Displayed in orange while setting is in progress

The display appears in red and green during RUN operation, but it changes to orange while setting is in progress, so that the sensor status can be viewed at a glance.

|

RUN operation [RUN mode]

|

|

| Red or green when output is ON / OFF |

|

|

While setting [MENU SETTING mode] [PRO mode]

|

|

| Orange while setting is in progress |

|

Default settings that can be used straight away

Easy-to-use default settings are provided for applications that are used frequently by pressure sensors. The default settings for low pressure types are ideal for suction confirmation applications, and those for high pressure types are ideal for checking reference pressure.

Buttons with good clicking touch

The buttons have a good clicking touch, allowing smooth setting.

Reset function

If a problem ever occurs with the sensor settings, they can be reset to the default settings.

All lineup models are compound pressure types

|

No sensor settings are required to switch between positive pressure and negative pressure, so that the number of registered part numbers can be decreased.

|

|

High performance accomplished [Low pressure type]

The low pressure type displays measurements in 0.1 kPa at a resolution of 1/2,000 and has a response time of 2.5 ms (variable up to 5,000 ms), ±0.5 % F.S. temperature characteristics and ±0.1 % F.S. repeatability, achieving high detection performance.

<Displays measurements in 0.1 kPa>

Resolution: 1/2,000

Response time: 2.5 ms

Temperature characteristics: ±0.5 % F.S.

Repeatability: ±0.1 % F.S.

Equipped with independent dual output [Standard type]

Equipped with two independent comparative outputs, and separate sensing modes can be selected for each of them. Since there are two comparative outputs, one of the comparative outputs can even be used for alarm output. In addition, output, which is not being used, can be disabled.

|

Vacuum breakdown can also be notified during suction applications!

|

|

|

|

Reference pressure alarm output is possible during reference pressure checking!

|

|

|

Three output modes are suitable for a wide range of applications

|

1. EASY mode

This mode is used for comparative output ON / OFF control.

|

|

|

Notes:

1) Hysteresis can be fixed to one of eight different levels.

2) "P-1" appears in the sub display for comparative output 1, and "P-2" appears for comparative output 2.

|

|

|

2. Hysteresis mode

This mode is used for setting comparative output hysteresis to the desired level and for carrying out ON / OFF control.

|

|

|

Notes: "Hi-1" or "Lo-1" appears in the sub display for comparative output 1, and "Hi-2" or "Lo-2" appears for comparative output 2.

|

|

|

3. Window comparator mode

This mode is used for setting comparative output ON and OFF at pressures within the setting range.

|

|

|

Notes:

1) Hysteresis can be fixed to one of eight different levels.

2) "Hi-1" or "Lo-1" appears in the sub display for comparative output 1, and "Hi-2" or "Lo-2" appears for comparative output 2.

|

|

Possible to switch over analog output and external input [Multi-function type]

Multi-function type of Ver. 2 is newly equipped with analog current output, in addition to analog voltage output.

Multi-function type that enables the selection of analog output (voltage / current) or external input (auto-reference / remote zero-adjustment) is available. It complies a wide range of applications.

Equipped with auto-reference / remote zero-adjustment functions, More precise pressure management is achieved with a minimum of effort [Multi-function type]

If the reference pressure of the device changes, two functions are selectable. One is auto-reference function, which partially shift the comparative output judgment level by the amount that the reference pressure shifts. The other is remote zero-adjustment function, which can reset the display value to zero via external input. These functions are ideal for places where the reference pressure fluctuates wildly, or where fine settings are required.

|

Without auto-reference and remote zero-adjustment functions

Because the threshold level is fixed for conventional pressure sensors, changes in the reference pressure result in wrong decisions.

|

|

|

With auto-reference function applied

When auto-reference input is applied, the reference pressure "30" is added to the threshold level. If the reference pressure changes to "20" or "40", the auto-reference input compensates for this every time by changing the threshold level, so any variation in the filling pressure can be ignored.

|

|

|

With remote zero-adjustment function applied

When remote zero-adjustment input is applied, the reference pressure is forced to "0". If the reference pressure changes to "20" or "40", the remote zero-adjustment input adjusts the reference pressure to "0" every time the reference pressure changes, so any variation in the filling pressure can be ignored.

|

|

Sub display can be customized

The sub display can be set to indicate any other desired values or letters apart from the threshold value. This eliminates the need for tasks such as affixing a label to the device to indicate the normal pressure value.

Setting details can be recognized at a glance

The DP-100 setting details appear in the digital display. Because the settings are in numeric form that can be easily understood, it is useful such as when receiving technical support by telephone.

Peak hold and Bottom hold functions

The peak values and bottom values for fluctuating pressures can be displayed using the dual display.

Energy-saving design! Equipped with an ECO mode

This mode lowers the display luminance to cut power consumption by approximately 30 %. The displays can also be turned off completely to achieve a power saving of approximately 40 %.

Tight installation to panels is possible

|

An exclusive mounting bracket that is suitable for 1 to 6 mm 0.039 to 0.236 in panel thickness is available.

|

|

|

|

An exclusive mounting bracket that supports tight installation is available

Space savings can also be achieved even when an L-shaped mounting bracket is used.

|

|

|

|

・MS-DP1-1

|

|

|

|

・MS-DP1-5

|

|

|

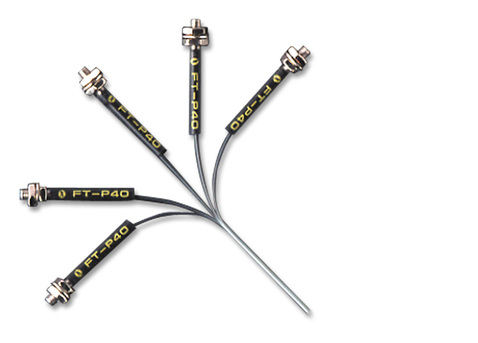

Cable can be connected with one-touch

Connector attached cable (2m 6.562 ft), as an accessory, can be connected easily with one-touch connection.

|

| * Options: 1 m 3.281 ft / 3m 9.843 ft / 5m 16.404 ft types are also available. |

|

|

Types without connector attached cable are also available [DP-10□-J]

Commercially-available connectors can be used for cable connections. Cables in required length can be used, so this contributes to reduction in waste of unwanted cables.

|

|

|

|

M8 plug-in connector types are also available (Only for Europe)[DP-11□E-P-J]

|

|

|

【Short pressure port type is lightweight and takes up little space】

Space saving!

|

Compact size with a depth of only 30 mm 1.181 in, so that it can easily fit into narrow spaces.

|

|

| * The illustration shows connection using an elbow joint. The elbow joint is sold separately. |

|

Light weight of 30 g! *

|

10 g lighter than standard types. This reduces the loads on movable parts such as robot arms.

|

|

| * Excluding cables with connector attached |

|

Ideal for clean environments!

10 g lighter than standard types. This reduces the loads on movable parts such as robot arms.

Rc1/8 conversion bushing is available. Compatible with previous model

[For short pressure port type]

By equipping the push-in converter with DP-10□-M(-P), pressure port can be converted from M5 female thread to Rc1/8 female thread. Bore diameter conversion to the DP2 / DP3 series is possible.

Flat installation on the wall by shifting the direction of the pressure port

[For short pressure port type]

By mounting the flat attachment to DP-10□-M(-P), pressure port and cable can now be pulled out in downward, left or right directions. Flat mounting on surfaces such as the wall is made possible.

| Model No. |

Pressure port |

| MS-DP1-FM |

M5 female thread |

| MS-DP1-FR |

Rc1/8 female thread |

| MS-DP1-FN |

NPT1/8 female thread |

| MS-DP1-FE |

G1/8 female thread |